Diapo

- Download our latest catalogue »

- Arch 356, Westgate Street London, E8 3RL

- Tel (+44) 020 7923 0006

- Fax (+44) 020 7923 0006

- Copyright & Trademark Notice

- © 2009 Diapo Limited

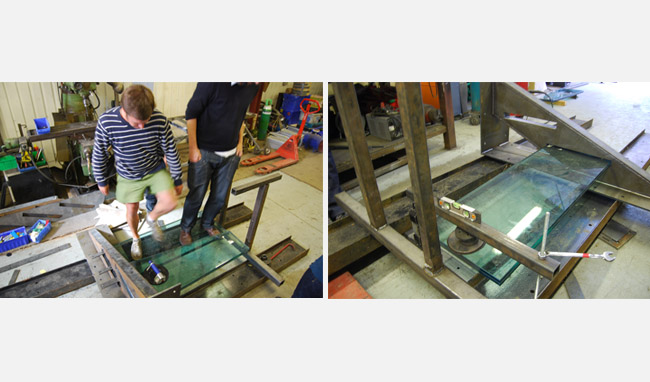

Gleneagles glass test rig

Before construction could begin on this spectacular staircase, some vital structural load tests had to be completed.

Under the guidance of Webb Yates engineers, a section of the proposed stringer was constructed in the workshop. Two glass treads were carefully inserted into the prototype clamping system, leveled and tightened into position.

Our intrepid designers were the first to step up and confidently test the integrity of their design. Of course, the rig and glass were plenty strong enough, and so the proper testing could begin.

Tension rods were used to apply a point load, via a load bar, to the end of the tread. A load cell was used to accurately confirm the applied load as it was incrementally increased to predefined targets.

At each stage the deflection was recorded, and the rig was then left for 5 minutes. The load (which by this point had decreased) was again recorded. The load was then released and the permanent deflection was recorded.

This process was repeated at 280kg, 560kg, 840kg and finally, an incredible 980kg! That’s more than 1.5 fully fuelled minis, or more importantly 4 times the required British standard.

We put this down as a pass and went into full production, the result of which will be posted shortly. Stay tuned for more pictures of this truly innovative piece of work.