Diapo

- Download our latest catalogue »

- Unit 3, Maskell Industrial Estate, 29 Bidder Street, London, E16 4ST

- Tel +44 (0)20 7993 2136

- Copyright & Trademark Notice

- © 2009 Diapo TM

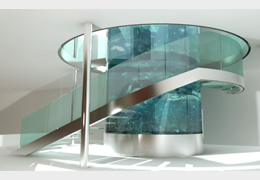

Following agreement on the initial design concept and budget, detailed design and written specifications are produced to enable production and implementation of the scheme.

Concept Development analyses how the product or interior can be designed to most effectively match your personal requirements. Our commitment to find the right, even inspired solution, is total.

This starts with the detailed production drawings which are produced for every component that is to be fabricated – only with this discipline can precision manufacturing take place and the subsequent accuracy and ease of on-site assembly be assured.

This starts with the detailed production drawings which are produced for every component that is to be fabricated – only with this discipline can precision manufacturing take place and the subsequent accuracy and ease of on-site assembly be assured.

We will then take the agreed design and resolve these into a fully detailed design towards manufacturing. Every issue is completely resolved from structural integrity to compliance with building regulation.

The component parts are manufactured and assembled in our workshops. Once assembled you will be invited to view the works at the factory.

The component parts are manufactured and assembled in our workshops. Once assembled you will be invited to view the works at the factory.

This assembly process allows us to finally check the whole structure before completion of all works and delivery on site. Our production team are dedicated craftsman in architectural fabrication, backed up by a range of sub-contracted partners who can bring their own specialists skills.

The focus at this stage is assembly of the architectural metal frame and quality of detailing prior to manufacturing of non-metalwork components.

The final stage is installation. Diapo uses their own team of skilled fitters under the close guidance of a Contract Manager to ensure the best result.

The final stage is installation. Diapo uses their own team of skilled fitters under the close guidance of a Contract Manager to ensure the best result.

This stage is broken down into three sub-stages:

(1) installation of structure and metalwork,

(2) installation of sub-contractors works (inc. wood, glass etc.) and

(3) aesthetic finishes.

The team will undertake the co-ordination of supply, production and installation of those items not directly fabricated by Diapo Ltd.